| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : KADAM

Model Number : None

Certification : RoHs, Reach, MSDS...

Place of Origin : China

MOQ : 50KG

Price : Negotiatable

Payment Terms : T/T in Advance

Supply Ability : 300MT per month.

Delivery Time : 5-8 work days.

Packaging Details : Plastic Drum

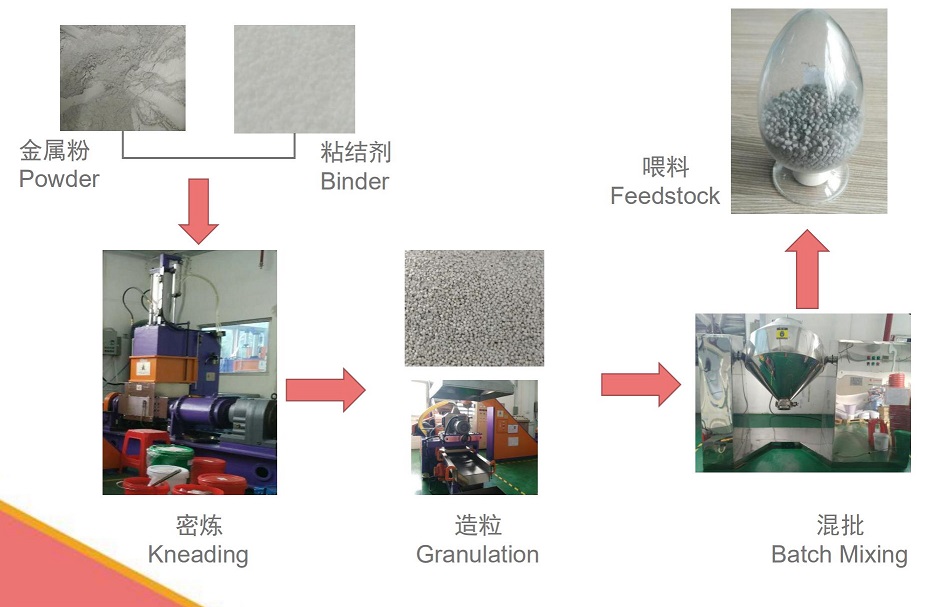

Product Name : MIM Feedstock

Brand : KADAM

Certificate : ROHS & REACH

Type of Substrate : Carbonyl

Shape : Grain

Size : Standard

Delivery Terms : FOB Shenzhen Port

Package : Plastic Bucket

MOQ : Could be Negotiatable

Application : All available

Fabrication Type : POWDER INJECTION MOLDING

KDM-HK30 High Alloy Heat Resistant Steel with Austenite Ferrite Dual Phase Structure

Model No.: KDMHK30

Type Of Substrate: Gas Atomization

Specification: High Alloy Heat Resistant Steel with Austenite Ferrite Dual Phase Structure

Product Description

Product DescriptionProduct Standard:

| Item | Unit | Specification | Test method |

| Melt flow index (MFI) | g/10min | 1000±500 | ISO1133 |

| Green part density | g/cm3 | 5.38±0.03 | ISO3369 |

| Sintering density | g/cm3 | >7.6 | ISO3369 |

Standard Processing:Standard injection molding machine for thermoplastic resins, based on the nitric acid catalytic debinding system.

Injection Molding:

| Injection temperature | Zone 1 | Zone 2 | Zone 3 | Nozzle |

| 180℃ | 185℃ | 190℃ | 195℃ | |

| Mold temperature | 90 ~ 125 ℃ | |||

| Screw speed | 50 r/min | |||

| Injection speed | 10 cm3/s | |||

| Molding pressure | 900 bar | |||

| Holding pressure | 900 bar | |||

| Holding time | 0.1~3 s | |||

How to work with us:

1. Send us 3D drawing (STEP/IGS/SolidWorks format etc. )

2. Specify the requirements (quantity, material, and surface finish requirements etc) to us via email.

| Manufacturing range | MIM Metal Injection Molding |

| Application | Any Industry, All customized. |

| Applicable Material | stainless steel/titanium/brass/copper etc. |

| Our advantage | 1. Rich experience in metal injection molding field. 2. Small order accepted for the beginning 3. New material develop capability. 4. Top quality guaranteed by skilled workers, managing system and status of facilities. 5.100% quality inspection before delivery |

| Surface finsih | Natural machined color/anodized finish/ coating / Passivation / PVD finish/nickel white/brush/heat treatment/fine glass beads/grounding/tumbled finish etc. |

| Payment Terms | 50% deposit before production and 50% balance before arranging to ship |

|

|

Ferrite MIM Powder Metallurgy Metal Injection Molding REACH Dual Phase Structure Images |